Our industrial mechanics solutions

Mechanical design and implementation, integrated to our activities

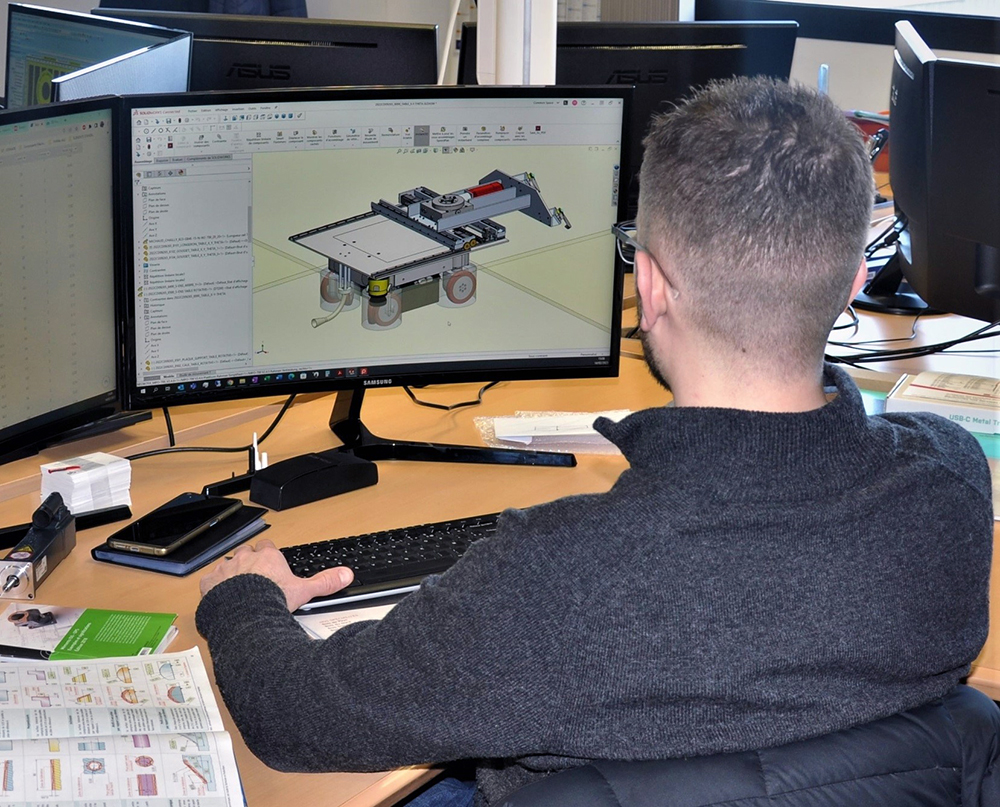

SBPROCESS has chosen autonomy, by integrating both mechanical studies and mechanical implementation in its offer.

We carry out studies, integration and implementation of our mechanical solutions, in full collaboration with our robotics, automation, and speed variation activities.

We can work on existing or developing production processes.

Our customers are mainly industrial companies, and our solutions offer a wide scope of applications (assembly, handling, packaging, …).

We study and design mechanical solutions, in accordance with your production objectives.

.

Supporting your industrial mechanics projects

- Translating your needs into technical and functional specifications, in collaboration with the robotics, automation and speed variation requirements

- Designing innovative and appropriate technical proposals, which are relevant regarding your productivity, ergonomics and maintenance requirements

- Integrating gripping solutions in your automated processes

- Studying the technical feasibility of the considered solutions, then conducting tests

- Monitoring the sub-contracting activities for machined parts

- Carrying out the assembly and the finalisation in our workshops then in our customer’s facilities

- Offering technical support to the users (operation, maintenance, …)

Supporting your industrial mechanics projects

- Translating your needs into technical and functional specifications, in collaboration with the robotics, automation and speed variation requirements

- Designing innovative and appropriate technical proposals, which are relevant regarding your productivity, ergonomics and maintenance requirements

- Integrating gripping solutions in your automated processes

- Studying the technical feasibility of the considered solutions, then conducting tests

- Monitoring the sub-contracting activities for machined parts

- Carrying out the assembly and the finalisation in our workshops then in our customer’s facilities

- Offering technical support to the users (operation, maintenance, …)

An agile and proven methodology for your mechanical projects

To develop an industrial mechanical solution that perfectly meet your needs, we deploy a 5-step approach:

Studying

Feasibility study based on the specification

Step 1

Designing

3D designing the solution with the Solidworks software, in accordance with the functional analysis and the risk analysis

Step 2

Approving

Client approval of the studies, Redaction of the technical file (2D plans, notice, ...)

Step 3

Manufacturing

Manufacturing, assembling, finalising and testing parts in our workshop

Step 4

Installing

Installing and commissioning on our customer premises

Step 5

6 good reasons to combine

automation and mechanics

Mastering the design, budget, and deadlines

Controlling the quality

Ensuring the alignment between the mechanical solution and the automation

Mastering the technical documentation

Allowing the solution to evolve all along its life cycle

Ensuring the regulatory compliance, as well as the compliance with the Machinery Directive

You would like to know more about it? To discuss your project with us?

Contact us at +33 (0)4 74 69 42 15