Special machines

Designing and manufacturing special machines

In order to meet their customers’ specific needs in terms of R&D or production, SPProcess develops and implements special machines which can complete any operation in an automated way.

The process applications for these special machines are diversified: winding/unwinding, assembling, bonding, handling packaging, measuring, …

These special machines can help maximise productivity, via the automation/robotisation of tasks previously made by operators, or via the improvement of cycle times.

The approach we offer for special machines projects is focused on answering the customer need.

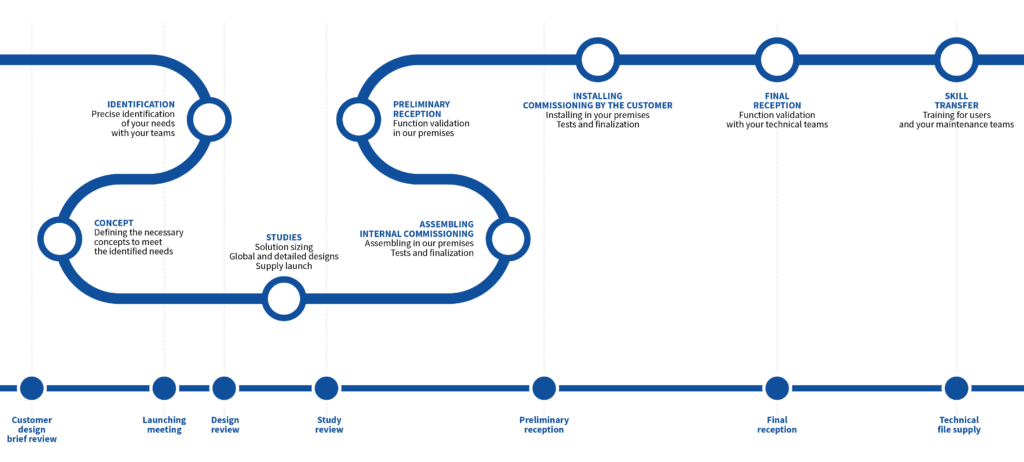

After meeting the customer to identify this need, we develop concepts, quantify their potential and then present them to the customer for approval. Only once these concepts are approved do we start extensive studies of the solutions, by coordinating all the activities necessary for the design (mechanics/automation/robotics/vision).

For more efficiency, we do assemble and finalize our machines inside our own facilities. Our customers are then invited for a preliminary delivery, in order to confirm the functionality of the machine in regard to the need they expressed at the beginning of the project. This preliminary delivery greenlights the transport, installation, and commission on the customer premises, which result in the final delivery of the machine, followed by training courses for the end users and maintenance teams (training included in the project).