Examples of construction of special machines

Milling and cutting special machine

Customer need

Task automation for the milling and cutting of plastic pipes at a specific length, while following entirely configurable settings defined by the user

Scope of supply

Comprehensive mechanical design of the machine

Developing the automation and setting management

Integrating and programming a robot for milling

Designing an automated saw for cutting

Advantages

Entirely automated production system

Driving ergonomics through the Man-machine interface

Production flexibility via settings and reference library

Milling and cutting quality

Safety: workstation complying with the Machinery Directive

Do you have a project concerning the construction of a special machine?

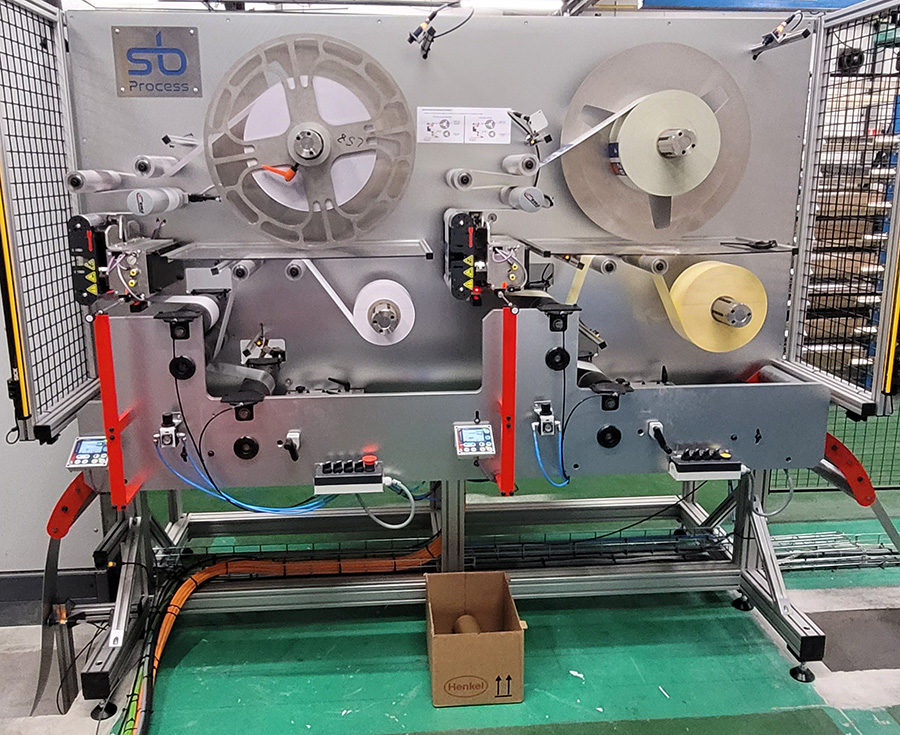

Dual laminate process special machine

Customer need

Film fitting via laminate process

Scope of supply

Mechanical design and integration

Developing the automation and line interfacing

Speed control depending on the line advancing through a sensor to manage the loops in the pits

Torque management for the rewinders and unwinders in case of material changes, through a diameter measure via ultrasound sensors

Integration into pre-existing production lines

Advantages

Speed: up to 30m/min

Material stretching management up to 20mm

Film lateral position precision lower than 0.5mm

Line output: 1 plate every 1.5s

Driving ergonomics through the Man-machine interface

Safety: workstation complying with the Machinery Directive

Do you have a project concerning the construction of a special machine?

Canula fitting special machine

Customer need

A mobile unit that can automatically drop plugs into cases on the customer production line

Scope of supply

Mechanical design and integration

Developing the automation and line interfacing

Integrating a vibrating bowl system to supply plugs

Finalizing the vision system (plug orientation detection)

Finalizing the robot (SCARA) and the gripping system

Preliminary delivery on our premises

Final delivery at the customer facility

Final delivery and commissioning at the customer facility

Advantages

Enhancing the operator workstation

Optimising the cycle time (up to 60 lay/minute)

Driving ergonomics through the Man-machine interface

Safety: workstation complying with the Machinery Directive