Exemples de réalisations de rétrofits

Examples of retrofitting for unwinders

Customer need

- Retrofitting a voltage control system

Scope of supply

Replacing a rheostat with a AC30 variator by unwinder

Integrating a Siemens automaton

Changing the motors (Weg)

Full compliance of the circuit diagrams

Making an electrical cabinet

Replacing the entirety of cables and wiring

Advantages

Easy use for the operator

Precise management of the voltage instructions

Resolving component obsolescence

Control system centralization through communication with the production line

Do you have a retrofitting project for your facilities?

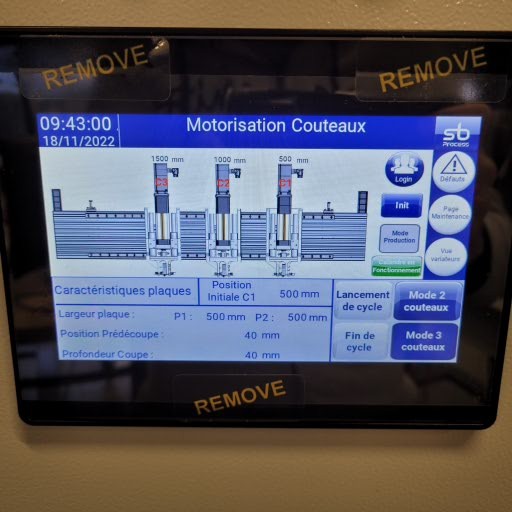

Retrofitting example for a panel cutting line

Customer need

Automation for the panel cutting of plastic rollers

Scope of supply

Mechanical design and integration of a positioning subset for motorized knives (lateral positioning and material recession)

Developing the automation and line interfacing

Integration into pre-existing production lines

Advantages

Panel width configuration (usable width and waste)

Precise management of the knife recession

Driving ergonomics through the Man-machine interface

Do you have a retrofitting project for your facilities?

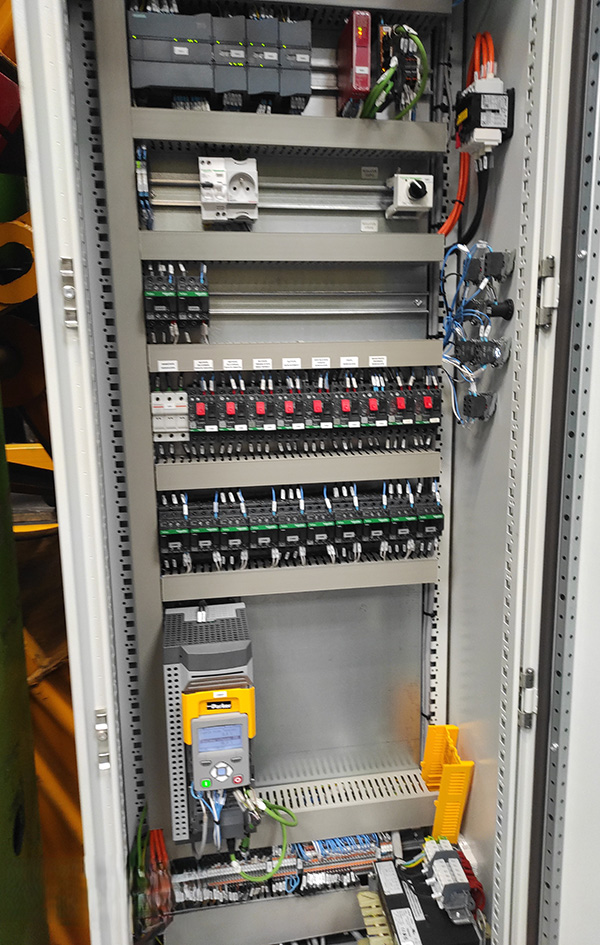

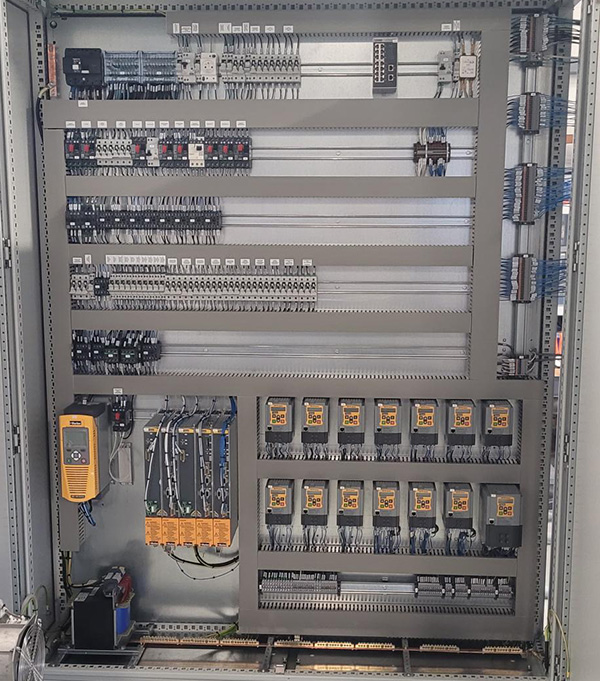

Retrofitting example for a complete production line

Customer need

Retrofitting a manufacturing, assembling and stacking line

Scope of supply

Changing the brushless motors (Weg)

Changing the variators (Parker)

Changing the automaton (Schneider)

Changing the linear axes

Program rewriting

Implementation of two MMI

Making the electrical diagrams and cabinets

Advantages

Investment continuity on the production line via obsolescence resolving

Line operation reliability

Implementation of a remote control for automation, motion and speed variation

Do you have a retrofitting project for your facilities?

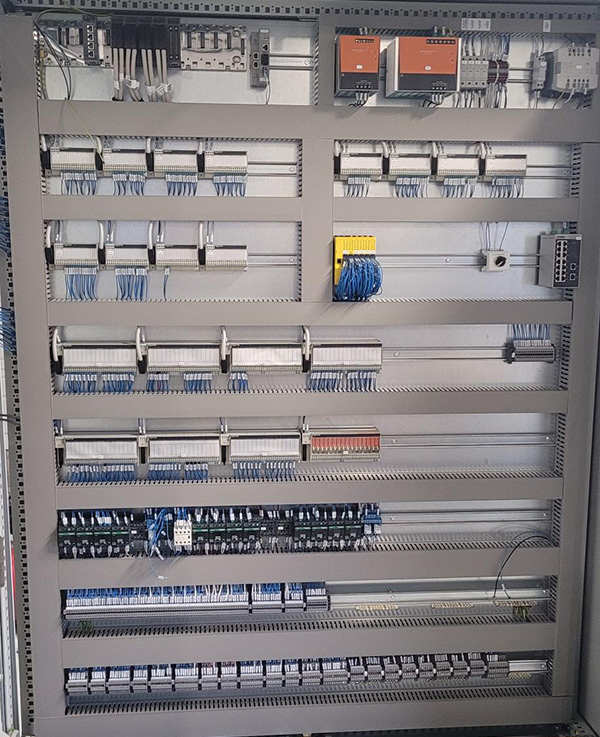

Example of retrofitting for a rotary table

Customer need

Retrofitting the system for one of their turntables

Scope of supply

Screening and sizing the solutions suited for the application: MMI (man-machine interface), automatons, variators, encoders, ...

Integrating new machine control functions

Full compliance of the circuit diagrams

Construction of the electrical cabinet

Final delivery and commissioning at the customer facility

Advantages

Driver ergonomics by integrating a MMI

New cabinet with guaranteed and more reliable standard components

Maintainability of the equipment